FEATURES:

- The major parts are manufactured from Meehanite cast iron,

heat treated for deformation free performance.

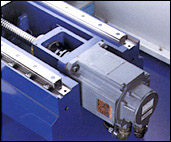

- High precision C3 class, ø40mm Ballscrew,

combined with preloaded double nuts for high positioning accuracy.

- Fully enclosed chip guard

- The square slideways are hardened, precision ground and coated

with Turcite-B for smooth traverse and maximum wear resistance.

- The spindle is driven by a powerful 7.5kw motor

|

- Geneva type automatic tool change system

- Magazine loading capacity is 16 tools.(24 tool option)

- Telescopic guards on three axes provide dependable protection

- Drawer type chip pan provides convenient chip handling.

- All axis are laser calibrated and ball bar tested, accuracy

charts are supplied with each machine.

- CE compliant versions

|

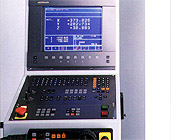

Controller

|

FANUC 0-M CNC

Controller

- 3 axis spindle 4th axis option.

- Auto Accel/Decel

- Manual continuous feed

- Auto coordinate system

- EIA/ISO auto recognition

- Mirror image

- Tool offsets

- Tool length compensation

|

WIDE OPENING

DOORS

¡@Front sliding doors open wide to allow easy access to work

area. |

|

MITSUBISHI M-530

CNC Controller

- 3 axis spindle 4th axis option.

- Tool offsests

- Canned cycles

- Mirror image

- Linear angle

- Exact stop check mode

- Sub program call

- Program error display

|

LINEAR

GUIDEWAYS

Optional THK "NR" type linear guideways. |

|

HEIDENHAIN TNC

410 CNC Controller

- 3 axis spindle 4th axis option.

- CRT colour monitor

- Look ahead for high speed contouring

- HR 410 Handwheel

- Tool measurement

- Helix Interpolation

|

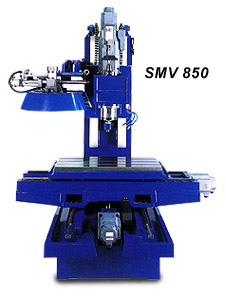

Meehanite construction of all axes and

heavy duty components ensure high rigidity for stable

cutting. |

|

SMV 850 shown with THK Linear Guideways

on X and Y

axis, Z axis has rigid box way construction

|

AUTOMATIC TOOL

CHANGE

The machine employs Geneva type tool change system.

The magazine loading capacity is 16 tools. Tool selection method is

bidirectional, random, the shortest path selection.

HIGH PRECISION SPINDLE STOCK

7.5 KW motor drive permits

for powerful cutting. The driving gears are hardened and precision

ground. Spindle runs on precision angular contact ball bearing,

ensuring high precision long time continues running

RIGID AND STABLE BASE

The base is manufactured from

high quality Meehanite cast iron. The three axes slideways are

hardened, precision ground and coated with Turcite-B. The heavy duty

Ballscrews combined with preloaded nuts for high positioning

accuracy and zero backlash. |

SPECIFICATIONS

| Model |

SMV-650 |

SMV-850 |

| Table |

Table size |

800x450mm

(31.5"x17.7") |

1000x450mm

(39.3x17.7") |

| Travel ranges

(X/Y/Z) |

650/500/500mm

(25.6"/19.6"/19.6") |

850/500/500mm

(33.4"/19.6"/19.6") |

| Spindle nose to table

top |

150-650mm

(5.9"-25.6") |

150-650mm

(5.9"-25.6") |

| Column surface to center of

table |

240-740

(9.4"-29.11") |

240-740mm

(9.4"-29.11") |

| Max. load capacity |

350kgs(770lbs) |

450kgs(990lbs) |

| Spindle |

Spindle taper |

BT40 |

BT-40 |

| Spindle speed (RPM) |

80-8000 |

80-8000 |

| Spindle center to column front

surface |

480mm(18.8") |

480mm(18.8") |

| Feed

Rate |

Rapid feed rate X,Y&Z axes

(mm/min) |

12000mm

(472"/min) |

16000mm

(630"/min)

/Z:12000

(472"/min) |

| Cutting feed rate

(mm/min) |

5000mm

(196.8"/min) |

5000mm

(196.8"/min) |

| Motors |

Spindle motor |

7.5KW |

7.5kw |

Feed motors

X & Y

axes |

MITSUBISHI |

2KW 2000r/min |

2KW 2000r/min |

| FANUC |

1KW 2000r/min |

1KW 2000r/min |

| HEIDENHAIN |

2.4KW 3000r/min |

2.4KW

3000r/min |

Feed motors

Z

axes |

MITSUBISHI |

2KW 2000r/min |

2KW 2000r/min |

| FANUC |

1KW 2000r/min |

1KW 2000r/min |

| HEIDENHAIN |

2.7KW 3000r/min |

2.7KW

3000r/min |

| Coolant pump |

1/2HP |

1/2HP |

| Lubrication pump |

100 Watt |

100 Watt |

Automatic

Tool

Changer |

No. of tools |

16 Tools |

16 Tools |

| Max. tool diameter |

80mm(3.1") |

80mm(3.1") |

| Max. tool length |

250mm(9.8") |

250mm(9.8") |

| Max. tool weight |

7Kgs(15.4lbs) |

7Kgs(15.4lbs) |

| Miscellaneous |

Air supply |

6 kg cm²(85psi) |

6 kg

cm²(85psi) |

| Power

requirement (KVA) |

12 |

15 |

| Machine dimensions |

3045x2345x2500mm |

3045x2345x2500mm |

| Machine weight |

5800kgs |

6200kgs |

*Finetech reserves the right to change any specifications

and or colors without prior notice.

Standard

Accessories:

- Tool box & tools

- Leveling blocks & bolts

- A.T.C. equipment

(Geneva type)

- Coolant unit

- Full enclosed splash guard

- Central lubrication

- Quartz work light

- Spindle air blast

- Alarm lamp

- 220/3/60 electrics

- Rigid Tapping

|

Optional

Accessories:

- 4th axis rotary table

- Chip conveyor

- Transformer

- 20 Tools ATC (Geneva type)

- 24 Tools ATC (Arm type)

- Coolant through spindle

- Graphic (FANUC)

- Spindle speed/Load meter

- Liquid cooled Spindle

- 10,000 R.P.M Spindle

Control Systems:

| Heidenhain |

TNC 410

TNC 426

TNC

430 |

| Fanuc |

Series 0 |

| Mitsubishi |

M 530

M 64 |

| Siemens |

Sinumerik 810D

Sinumerik

840D | | |