EDGE BELT POLISHING

MACHINE semi-automated cutting, profiling and

milling machine semi-automated

cutting & shapingworking machinery semi-automated cutting & shaping working

machinery Marble

grinding machine (automatic) Granite cutting machine OEM/ODM

MANUFACTURE TAIWAN CHINA

Likest Corporation

OEM/ODM WELCOME

LD2000 semi-automated cutting, profiling and milling machine

Contact

us BACK

HOME

semi-automated cutting &

shapingworking machinery

DIA POLISHER BELT

|

¡@ |

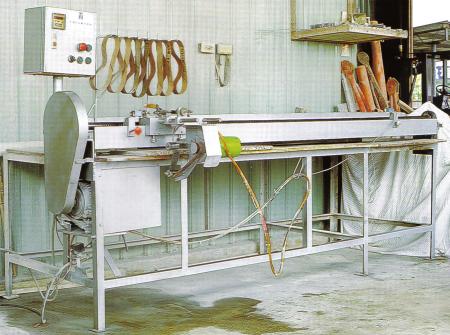

EDGE BELT POLISHING MACHINE

. |

|

INTRODUCTION

EASY Operation and Setting!

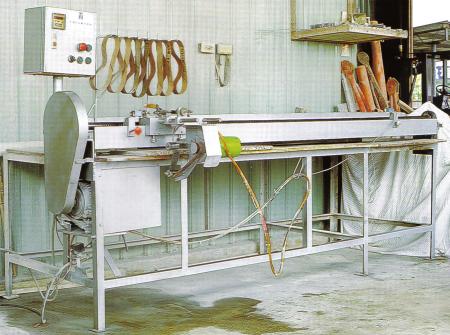

The Edge Belt Polishing Machine is the revolutionary stone polishing

machine that is simple to use, energy-efficient and cost effective.

With its high accuracy and high stability features, this machine can

handle thickness ranges and lengths that exceed other belt polishing

machines in its class. |

|

| ¡@ |

|

| ¡@ |

Contact us for more product information

|

|

|

|

| ¡@ |

- HIGH ACCURACY |

| ¡@ |

- HIGH STABILITY |

| ¡@ |

- EASY TO OPERATE |

| ¡@ |

- EASY TO INSTALL |

| ¡@ |

-

COST EFFECTIVE |

|

| ¡@ |

A new and improved system for polishing of granite, marble

and homogeneous tile edges. Thickness ranges from 10 - 50mm and

offers a big reduction in work time, a huge cut in production costs

and a degree of polish that is better than that of slab surface.

The

machine will easily polish a stone with length ranging from 100mm to

3,000mm. (Upon request, other lengths are also available).

With

this new, simple, efficient and economical system that comes with a

sturdy mechanical structure, stone polishing will never be the same

again

Functions:

1.New type motor

to save power.

2.Press the ON/OFF button, it will grind automatically and spray

water to save manpower.

3.It can set up the frequency of cycles then stop automatically.

4.It can grind into polishing straight line without distorting.

This Polishing Machine can for beveller edges mostly rounded

profiles of stone.

Set a machine on "L" shape guide rail, so, everyone can easily work

by very simple operation. |

¡@ |

|

|

| ¡@ |

TECHNICAL DATA |

| ¡@ |

Motor: |

Pneumatic, speed from 0 - 4,000 RPM (Continuous speed pre-selection) |

(0.16KW) |

| ¡@ |

¡@ |

¡@ |

¡@ |

| ¡@ |

¡@ |

Electrical, speed from 2,000 - 6,500 RPM

(Continuous speed pre-selection) |

(1,200Watts) |

| ¡@ |

¡@ |

¡@ |

¡@ |

| ¡@ |

Slab Thickness: |

10-50 mm |

¡@ |

| ¡@ |

¡@ |

¡@ |

¡@ |

| ¡@ |

Total Weight: |

12 kg (Without the L Frame) |

¡@ |

¡@

| ¡@ |

OPTION

EQUIPMENT |

| ¡@ |

1

no. x Guide Carriage with length totaling 900mm

(other lengths

available upon request) |

| ¡@ |

1

no. x Polishing Belt length 670mm x 40mm Grit # 60 |

| ¡@ |

1

no. x Polishing Belt length 670mm x 40mm Grit # 100 |

| ¡@ |

1

no. x Polishing Belt length 670mm x 40mm Grit # 200 |

| ¡@ |

1

no. x Polishing Belt length 670mm x 40mm Grit # 400 |

| ¡@ |

1

no. x Polishing Belt length 670mm x 40mm Grit # 800 |

| ¡@ |

1

no. x Polishing Belt length 670mm x 40mm Grit # 1,500 |

| ¡@ |

1

no. x Polishing Belt length 670mm x 40mm Grit # 3,000 |

| ¡@ |

1

no. x Polishing Belt length 670mm x 40mm Grit # BUFF |

Perfect fitting and sharp cutting by CPM-DIA BELT.

¡@

| ¡@ |

1

no. x Air Hose |

1

no. x Water Hose |

| ¡@ |

1

no. x Open End Wrench |

1

no. x Splash Guard |

| ¡@ |

1

no. x Side Handle |

1

no. x Stop Guard |

|

Profiles that can be polished with our system. |

|

|

Marble

grinding machine (automatic)

Marble

grinding machine (automatic)

Marble

grinding machine (manual)

Marble

grinding machine (manual)

Functions:

a. Easy of operation and installation.

b. Suitable for CPM-DIA belt.

It will be perfect installation and sharp cutting.

This is for:

a. Polishing machine of mostly round lateral stone to be cut into oblique angle

edge.

b. Place a machine on L shape sliding rail so that everyone may operate with

simple method easily.

¡@

¡@

¡@

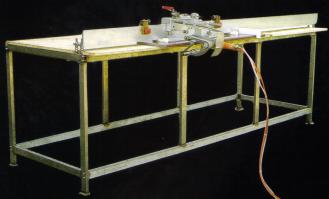

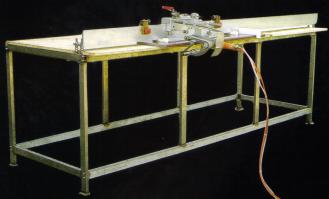

The

LD2000 semi-automated cutting, profiling and milling

machine that was design for high output, easy operation, very low

maintenance with excellent reliability. Extremely stout structure free from

vibration. Table movement on high steel guide submerse in oil resulting in

zero wear and tear. Electric plant and control panel from international

brand, 100% water resistant. Major machine movement equip with sensor for

precise movement.

Waterworks complete with all necessary hoses and valves.

For further information, please contact us |

¡@ |

|

¡@ |

|

|

| ¡@ |

¡@ |

Side view showing 45 degree angle cut & HOGH

POWER main motor + control panel |

¡@ |

|

|

| ¡@ |

|

|

|

| ¡@ |

|

¡@ |

¡@ |

|

|

| ¡@ |

¡@ |

The

LD2000

ready for

delivery to our next customer! |

¡@ |

| ¡@ |

¡@ |

|

| ¡@ |

Top view of our

LD2000

with detail

of main motor, well seal electric box and low tension control box |

¡@ |

| ¡@ |

| ¡@ |

|

¡@ |

|

| ¡@ |

LD2000

handwheel for table movement with detail pic

of "EASY INTERCHANGEABLE CHAIN" |

¡@

|

|

¡@ |

¡@ |

¡@ |

¡@ |

¡@ |

| ¡@ |

¡@ |

We release the new semi-automated

cutting & shaping working machinery with the following characteristic:-

-

Cutting head with up & down

motion with 45 degree cutting ( 90 degree optional )

-

Attached with " easy adjustment

" end-cutting gauge.

-

Functional control panel

-

5 H.P main motor.

-

Diameter of blade from 200mm

onward, maximum 350mm

-

Standard cutting dimension of

1200mm x 1200mm. Other size optional.

|

Granite

cutting machine (automatic)

Granite

cutting machine (automatic)

Functions:

Press the ON/OFF button, it will automatically put out the cutter to spray and

cut.

The cutting tool will ascend automatically after cutting to save cutting tool

worn out rate for 40%.

Features:

The cutting tool may turn around for replacement of granite molded cutter

housing.

It can the semi-circle and full-circle cutting.

One machine serves multiple purposes.

Contact

us BACK

HOME

Marble

grinding machine (automatic)

Marble

grinding machine (automatic) Marble

grinding machine (manual)

Marble

grinding machine (manual)

Granite

cutting machine (automatic)

Granite

cutting machine (automatic)