CNC Wire Cut EDM, CNC Wire Cut EDM Machining, CNC Wire Cut EDM Machine manufactured in Taiwan and listed in this machine tool search engine highlighting online VIDEO service,Accutex- CNC Machine Tools, CNC Wire Cutting Machines, CNC Machines, EDM Machines, Wire Edm Machine, Flushing Cutting Machines, WEDM Manufacturer.CNC Machine Tools, CNC Wire Cutting Machines, CNC Machines, EDM Machines, Wire Edm Machine, Flushing Cutting Machines, WEDM Manufacturer.Wire Cut EDM, Wire Cut EDM Machine, Wire Cutter EDM, Wire Cut Electric Discharge Machine-Taiwan, China Wire Cut EDM, China Wire Cut EDM Machine, China Wire Cutter EDM, China Wire Cut Electric Discharge Machine Manufacturers With Video On Line, supplier, exporters.

MACHINE FEATURE

NEW TECHNOLOGY WIRE CUTTING

MACHINE

WITH DIGITAL CONTROL FOR HIGH QUALITY FINISH

¡@

EDM Hole Drilling Machine CNC EDM

Maximum cutting speed up to 200 mm

/min

ROBUST STRUCTURE MAIN FRAME

- Long-lasting working table made of stainless steel.

¡@- High rigid arm to secure the precise cutting.

¡@- High precision digital readout scale on all 4-axes.

¡@- High precision linear guide and ball screw on slide way.

RELIABLE STABLE QUALITY WIRE CUT.

- Well-balanced design with rigid frame to protect from being deformed by heavy load.

¡@- U and V axes independently lay over the column, sliding with linear guide way and ball screw to secure the high stability while cutting.

¡@- Longer traverse on U, V axes to enable ¡Ó15

/ 60mm big angle cutting.

¡@- Final inspect with laser beam alignment to ensure top quality.

¡@MEDIUM SIZE WIRE CUTTING

FOR THE BEST FINISH IN THE FIELD¡@¡@

¡@

SPECIAL DESIGN WITH HIGH EFFICIENT PERFORMANCE ¡@ ¡@ 1. Square type working table to hold the workpiece in any place for handy operation ¡@ ¡@ 2. Semi-auto wire threading for easy replacing ¡@ ¡@ 3. Providing mutiple cutting process with super fine finish function ¡@ ¡@ 4. Availability for the supply of the spare part ¡@ STAINLESS WORKING TABLE ¡@ ¡@ 1. Any fixture can be fitted on this square type table. ¡@ ¡@ 2. No deformity on the stainless table ¡@ THREAD CONTROLLING SYSTEM ¡@ ¡@ 1. Stabilizing the tension of thread for constant speed ¡@ ¡@ 2. Easy to replace for the thread and maintain it

WATER FILTER AND HIGH PRESSURE MOTOR ¡@ ¡@ 1. New watering system with paper filter for easy replacement ¡@ ¡@ 2. High pressure pump with inverter controlled by computer for various water flushing volume ¡@

CERAMIC THREADING WHEEL WITH GEAR ¡@ ¡@ 1. To enable using 0.15 mm thread with this design ¡@

PURE WATER TREATMENT ¡@ ¡@ 1. Stainless water tank with resistivity control sensor to ensure water conductivity within range ¡@

AUTO-VERTICAL RECTIFIER ¡@ ¡@ 1. Automatically rectify perpendicularity and measure height of diamond guide.

MODEL

|

M350 |

SERIES 350*250*200 |

| M540 |

SERIES 500*400*320 |

| M840 |

SERIES 800*400*320 |

CONTROLLER FEATURE

|

|

|

|

|

huichi |

| MEASURING DISPLAY Full measuring function by graphic display |

|

| MAINTENANCE Self-diagnostic function with alarm. |

|

| TAPER SETTING Parameter setting for taper is guided step-by-step from CRT |

|

| MONITORING PROCESS Zooming the workpiece with rotating display in cutting process |

|

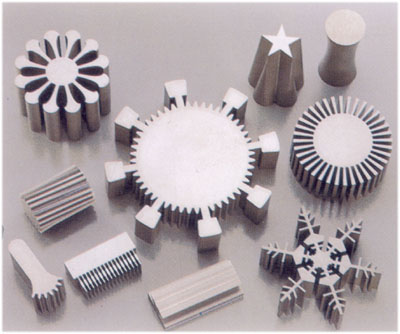

EXAMPLE

800*400*320

- High precision cornering control

- High sensitive auto servo feeding

- Multiple function taper cutting

- Multiple style cutting application

- Build-in graphic application

- High performance self-diagnostic system

MACHINE SPECIFICATION

| ITEM \ MODEL | unit | M350 | M540 | M840 | |

| MECHANISM | |||||

| Working type | FLUSHING | ||||

| Max capacity | mm | 700*500*200 | 1100*900*320 | 1400*900*320 | |

| Max workpiece | kg | 350 | 800 | 1000 | |

| Table to floor | mm | 900 | 1100 | 1100 | |

| Thread type | SEMI-AUTO | ||||

| Z-Axis device | Manual | Automatic | Automatic | ||

| X,Y Traverse | mm | 350*250 | 500*400 | 800*400 | |

| Z Traverse | mm | 200 | 320 | 320 | |

| U, V Traverse | mm | 50*50 | 100*100 | 100*100 | |

| Driver | servo drive | ||||

| Positioning | X, Y, U, V, Linear scale | ||||

| Table rapid feed | mm/min | 1200 | |||

| Max taper | 15/60mm | ||||

| Max wire-feed | m/min | 15 | |||

| Wire tersion | g | 200-2500 | |||

| Machine Weight | kg | 1800 | 3500 | 4000 | |

| Over all dimension(W*D*H) | mm | 3040*1650*1830 | 3620*2570*2210 | 4620*2570*2210 | |

| Max thread roll weight | kg | 6 | |||

| Wire diameter | mm | 0.15,0.20,0.25,0.30 | |||

| Perpendicularity rectify | Automatic | ||||

| Taper rectify | Automaitc | ||||

| WATER TREATMENT | |||||

| Tank capacity | L | 400 | 460 | 520 | |

| Filtering element | Paper filter cartridge | ||||

| Filtered-particle size |

|

5 | |||

| Pure water supply unit | Conductivity control | ||||

| Ion-exchange resin type | L | 5 | |||

| Coolant system | BTU | 18000 | |||

| CNC UNIT | |||||

| Axis control | X, Y, U, V | X, Y, U, V, Z | X, Y, U, V, Z | ||

| Min. setting | mm | 0.001 | |||

| Min. movement | mm | 0.001 | |||

| CRT display | 14" Color CRT display | ||||

| I/O device | RS-232C/3.5", 1.44MB FDD | ||||

| Graphic display | 2D/3D | ||||

| Program storage | 2.2GB HD | ||||

| CNC FUNCTION | |||||

| Axis rotating +/-360 | Mirror | X, Y lmage rotating | Offset | 99.000~999.000mm | |

| Scale 0.0~99.00 | Corner path | 0.0~100.0mm |

Cornering pause |

0~9999sec | |

| POWER SUPPLY | |||||

| Discharge

loop Transistor Pulse loop |

Discharge code |

0~255 | Current step |

1~9 | |

| Off-time 3~50 |

Auxiliary current |

1~5 |

Auxiliary Off-time |

5~50 | |

| Servo voltage 0~70 | Open voltage |

85V, 95V 115V |

Fine finish | Standard | |

OPERATING

| Start point return Restart |

Hold point return Dry run |

Path tracing Single block execution |

Path retrace Optional stop |

Start point Number setting Taper discharge |

| Optional skip System maintenance |

Background Program edit On-line help |

Background Program simulation Auto-perpendicularity rectify |

Subprogram Auto edging |

MDI Soft limit setting |

| Self-centering Half coordinate |

Self-O.D.-centering Reference point set |

Self-centering in

slit Home return |

Axis rotating Mold change |

Macro setting Auto-taper rectify |

| Cutting length

display Cornering path Control |

Calculating

cut-length Alarm message |

Working timer I/O Status |

Cutting speed

display Ladder diagram |

Single block

simulation System status display |

EDM Hole Drilling Machine CNC EDM BROKEN TAP REMOVER Contact us