Welded steel wire fabric, automatic wire welder, chain-link fencing machine, wire nettings of metal Manufacturer in Taiwan Asia

Manufacturer for Wire Mesh Making Machinery Contact HOME

( 1) Wire Mesh, welded Wire Mesh, chain link fence, stainless steel Wire Mesh, welded Mesh, Mesh Wire, Wire Mesh Partition, Wire Mesh fencing, Mesh stainless Wire, Wire Mesh fence, fence, fencing, steel Mesh Wire, Wire Meshes belt. ( 2) security barriers, road block, barrier, police security road block barrier, traffic barrier, safety barrier, barrier gate, barrier entrance, police barrier, fence barrier, road barrier, entrance barrier, fence razor Wire, razor Wire security barrier, concertina Wire, concertina razor Wire, concertina barb Wire, barb Wire concertina, security. ( 3) chain link fencing machine, barbed Wire machine, hexagonal Wire netting machine, Wire Mesh welding machine, Mesh- making machinery, hexagonal gabion machine, gabion equipment, machine, machinery, automation equipment, automation system, machine automation, automated production system, construction equipment.. (4) conveyor, belting, metal conveyor, conveyor belt, Wire belt, conveyance, conveyor belt system.

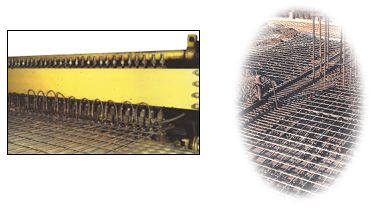

Semi-Automatic Wire Mesh Machine (P-Type)

|

Operation

|

||

|

1.

|

Manually feeding straight line wire to the spot welding position.

|

|

|

2.

|

Press the work piece by cylinder then fed by motor running.

|

|

|

3.

|

Reached to the spot welding system.

|

|

|

4.

|

Cross wire was fed by carriage with sole hopper.

|

|

|

5.

|

Feeding to the position then in the process of welding.

|

|

|

6.

|

Work piece was hold by holding system.

|

|

|

7.

|

Wire mesh completed.

|

|

|

Features

|

||

|

1.

|

Spot Welding System

|

|

|

|

According to wire pitch to adjust the up compressed cylinder,

electrodes, and fixture.

|

|

|

|

Able to set welding time and current individually.

|

|

|

2.

|

Cross Wire Feeding System

|

|

|

|

It is an auto single cross wire loading carriage and integrated with

the welding system.

|

|

|

|

It has 2 functions of auto wire ordering and outputting.

|

|

|

3.

|

Output Installation

|

|

|

|

It carry the welded mesh to next work station.

|

|

|

|

The required pitch is adjusting by servo motor and gripping pliers.

|

|

|

4.

|

Controlling System

|

|

|

|

Computer controlling system, easy for operators running and

maintenance.

|

|

|

Specifications:

120 KVA x 2 sets of

transformers.

Diameter of wire: ø2~ø10mm. Production capacity: 3.5 second/each wire. Size of mesh: W2400 mmx L3000mm W1800mm x L3000mm W1200mm x L3000mm 12 sets of cylinders can be operated & disengaged separately. It can also be adjusted according to the various requirement of production. Two sets of transformers on both sides of machine. 12 sets cylinders on top of machine. To separate the cylinders from the center of electrodes. Each time, two electrodes are descended for welding. Then electrodes descend automatically from the center to both ends, totally six times descending. The current is adjustable. While cross wires loaded into the mold, manually push the mold to welding position, then to operate the welding by foot paddle. It is the essential that the mesh product must be flat without distortion. This machine is designed for this purpose. |

Wire

Mesh Welding Machine

Wire

Mesh Welding Machine

MODEL NO.: CF-WM1000

WIRE MESH WIDTH (CROSS WIRE LENGTH): MAX 2500mm MIN 900mm

DISTANCE BETWEEN THE TWO OUTERMOST LINE WIRE: MAX.2400mm

LINE WIRE DIAMETER: 4.0 10.0mm

CROSS WIRE DIAMETER: 4.0 10.0mm

LINE WIRE SPACING, ABOVE STEPLESSLY PROGRAMMABLE: MIN. 75mm

CROSS WIRE SPACING, ABOVE STEPLESSLY PROGRAMMABLE: MIN. 50mm

NUMBER OF LINE WIRES (MAX.): 24

WIRE MESH LENGTH: 2000-6000mm

CAPACITY:

THE WORKING SPEED IS INFLUENCED BY THE CROSS WIRE SPACING, THE WIRE DIAMETER THE MESH WEIGHT, QUALITY OF WIRE MATERIAL, ETC. AND REACHES UP TO 40-80 CROSS WIRES PER MINUTE.

WIRE MATERIALS:

THE WIRE MUST BE READILY WELDABLE (UNALLOYED, CLEAN WIRE) AS USED IN THE REINFORCEMENT WIRE MESH SHEET PRODUCTION. THE LINE AND CROSS WIRES ARE FED TO THE WELDING MACHINE STRAIGHTENED AND CUT TO LENGTH. FOR THE PREPARATION OF THE LINE AND CROSS WIRES

STRAIGHTENING AND CUTTING OFF MACHINES WITH ROTATING SPINNER ARE REQUIRED.

WIRE ROLL WEIGHT (LINE WIRE MATERIAL ROLL)

LINE WIRE MUST BE PUTTED AS WIRE ROLL DELIVER INTO THE MACHINE

WIRE ROLL MUST ROLLED STRAIGHTLY AND THE MAX. WEIGHT IS 3000 KGS

ELECTRIC POWER:

THREE PHASE CURRENT: 220V

CONNECTION VOLTAGE: 60HZ

MAX. ELECTRIC POWER DEMAND: 800HP

(CROSS WIRE DIAMETER: 10+10mm SPACING: 100 X 100mm

NUMBER OF LINE WIRES:24)

COOLING WATER

INLET TEMPERATURE (MAX.): 25℃

PRESSURE DROP (MAX.):1.5BAR

PRESSURE: 3.5 BAR

CONSUMPTION APPROX.: 60L/MIN.

ONLY CLEAN, NEUTRAL TO SLIGHTLY ALKALINE WATER MAY BE USED.

Metal

Mesh Forming Making Machine

Metal

Mesh Forming Making Machine

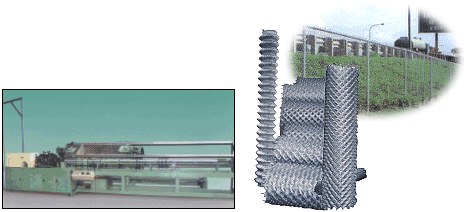

Auto Chain Link Fencing

Making Machine菱形網機

Auto Chain Link Fencing

Making Machine菱形網機

MODEL NO: CF-CLF-3100S

FENCE MESH PITCH: 1-4”

WIRE RANGE: 8# - 14#

Max. FENCE HEIGHT: 4M

MAIN MOTOR: 7.5HP

PRODUCING CAPACITY: 10# x 2”, 800m2/8HORS

CUTTING SET: 3HP

TWISTING SET: 2HP

WATER PUMPER: 1/8HP

EMERGENCY STOPPING SYSTEM

STANDARD EQUIPMENT –

TWO SETS OF DIES (SPEC. AS REQUIRED)

TWO SETS OF WEAVING PIPES

FLOOR SPACE: 8.1M x 4.5M

M/C WEIGHT: 3950 KGS/4200KGS

OPERATING VOLTAGE: AS REQUIRED

Max. Speed:1000 RPM

|

Compact & Ordinary Packing Recoiler Dual Function |

Stacker-Compact Packing |

Hexagonal

/ Hex Wire Netting Making Machine

(Reverse Twist)六角網機

Hexagonal

/ Hex Wire Netting Making Machine

(Reverse Twist)六角網機

MODEL NO: CF HEX100M

WIRE DIA: 0.7-1.0mm

MESH: 1” (25.4mm)

WIDTH: 1~3.5M

LENGTH: 100”/ROLL

PRODUCTION CAPACITY: APPROX.600 METERS/8HRS

MOTOR: 2HP

INCLUDING ONE BOBBIN STAND

ONE SET OF BOBBIN

ONE BOBBIN WINDING UNIT

★★MACHINE SIZE★★

MAIN MACHINE: 2.65M(W)X1.85M(L)X1.45M(H)

BOBBIN STAND-1.45M(W)X0.82M(L)X1.27M(H)

BOBBIN WINDING UNIT-1.38M(W)X1.3M(L)X1.3M(H)

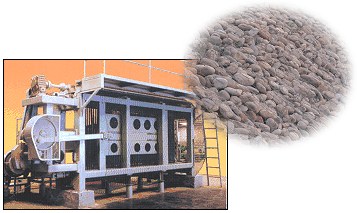

Hexagonal

/ Hex Wire Netting Producing Line (Gabion Weaving Machine & Equipments)石籠網機製造設備

Hexagonal

/ Hex Wire Netting Producing Line (Gabion Weaving Machine & Equipments)石籠網機製造設備

WEAVING MAIN MACHINE

(MODEL NO: CF-GABION)

WIRE DIA. 2.0mm ~ 4.0mm

MESH SIZE: 80mm X 100mm (AVAILABLE)

WIRE TYPE: GALVANIZED STEEL WIRE OR PVC

COATED WIRE

WORKING WIDTH: 2M, 3M, 4M (AVAILABLE)

SPEED: 40 STROKES/MIN

POWER: 7.5HP X 6P

COUNTER: 0-9999

AUTO-STOPPING DEVICE (broken wire or run out of material)

WT. 7800KGS

SIZE: 5150L X 960W X 3250H

WORKING PLATFORM

WITH FEEDING STRENGTHENER

Weight.: 700KGS

SIZE: 4320L X 2450W X 1740H

WIRE SPIRAL COILING UNIT

SPEED: 44M/Min (254 SPIRALS)

POWER: 1HP

Weight.: 490KGS

SIZE: 2500 X 980W X 1200H

WIRE STAND (PRODUCED BY BUYER)

Weight: 51KG/PC

SIZE: 850Ø X 460H

(WE WILL OFFER ONE PC OF SAMPLE STAND AND THE DRAWING)

|

Barbed Wire |

Barbed Wire Machine |

reverse-twist barbed wire machine |

|

reverse-twist barbed wire |

|

|

|

Razor Barbed Wire Making Machine

Production Speed:60 meter/minute |

|

Razor Barbed Tape Wire |

Razor Barbed Tape Wire |

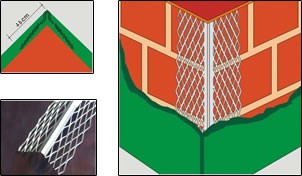

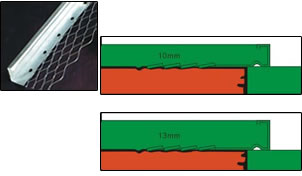

Angle

Bead / CORNER BEAD / Plaster Stop Bead

Production Line / Rib-Lath / Hi Rib-Lath Making Machine

Angle

Bead / CORNER BEAD / Plaster Stop Bead

Production Line / Rib-Lath / Hi Rib-Lath Making Machine