Corner Bead Making Machine

Products

Construction Expended Metal Making Machine, Automatic Rib-Lath Making Machine, wire mesh machine, expanded metal mesh, china wire mesh machine, wire mesh machine,expanded metal mesh machine,angle beads machine,rib lath making machine,hi rib formwork mesh machine,welded wire mesh machine,barbed wire machine,wire drawing machine,auxiliary machine,series electric welders,wire mesh product,expanded metal mesh,corner beads,rib lath,hi rib formwork mesh,welded wire mesh,hexagonal wire netting,galvanized square wire mesh,pvc coated wire mesh,galvanized wire,barbed iron wire,insect screening,stainless steel wire mesh,brass wire mesh

We are specialized in making expanded mesh equipment (expanded metal machine); checkered plate equipment; metal mesh

¡@

Construction Expended Metal Making Machine / Automatic Rib-Lath Making Machine / Corner Beads Machine (Angle Beads Machine) / Building Network Machine

|

Corner Bead Making Machine |

Products |

|

|

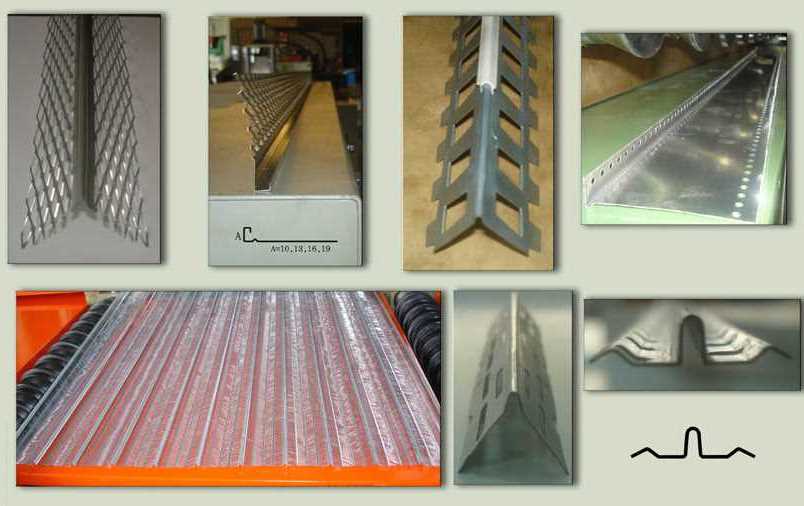

CORNER BEAD & PLASTER STOP BEAD LINE Metal Mesh Forming Making Machine Expanded Metal Bead Making Machine /

MAX OUTPUT:520 STROKES/MINUTE Movement Bead Making Machine /

Plaster Stop Bead Making Machine

| Rib-Lath / Hi Rib-Lath Making Machine Angle Bead / CORNER BEAD / Plaster Stop Bead Production/ METAL MESH FORMING MACHINE |

|

Angle Bead Making Machine

| Corner Beads (Angle Beads), also known as Corner Bead, is an important material for plaster decoration. Angle beads can form a straight line above the plaster angles to protect it from getting broken, at the same time, to protect and strengthen the fragile plaster. By using of angle bead can save considerable time of work. | ||||||||||||||||

| ¡@ | ||||||||||||||||

| The finished products: Kinds of different type of Corner Beads (Angle Beads) | ||||||||||||||||

| ¡@ | ||||||||||||||||

|

||||||||||||||||

| The Application of the Corner Beads (Angle Beads): | ||||||||||||||||

|

||||||||||||||||

Hy-Rib / Rib-Lath Production Line High RIB-Lath Making Machine

Model: CF-4450

Description:

Constructional Net Machine

Brief introduction :

We call the sharp template of the speed in high-strength muscle material metal network , it is one kind that does not have stencil plate net of contact, his stencil plate department is made of zinc-plated stencil plate , " U " type disconnected gluten material department of his network hole and rigidity cuts shaping through the special professional machine, it is specially strong not to have a contact that resist tension at all the network, high-strength muscle material metal network and already widely using for replacing and making the template up , and does not need traditional wooden template , therefore can save and beat , the artificial expenses of buying oil and wooden template necessary surface preparation , and the best strong material of benefit of project.

|

Applicable scope:

¡@ |

Specification:

¡@ |

Economic efficiency:

Weight light:

When high place is easy to transport the plasticity

In a big way: May cut at will, curving, makes any shape to provide the truly

Adjoining plane:

The concave-convex network structure surface has provided two

grouting

adjoining planes, avoided not truly taking time takes the trouble to

damage the work

(to be possible to avoid noise in tunnel, fell environmental

pollution and so on dust)

Constructs easily: Only must install, does not have to demolish and so on the work

Reduction pressure cleanly:

The open style mesh is helpful in the concrete moisture

Reduction pressure cleanly: The truly foundation structure and avoids two times of grouting having the sequela which the cold seam creates to

Maintain the nature resources:

The substitution tradition wooden mold, reduces the forest

massively to mine

Products

Rib Lath Machines

Model: CF-6860 & CF-6100

¡@

Description:

¡@

Rib Lath Machines

|

Applicable scope : 1.Structure

joint construction joint. ¡@ |

Specification : 1.

Thickness: 0.4~0.5mm. ¡@ |

Angle Bead / CORNER BEAD / Plaster Stop Bead Production Line / Rib-Lath / Hi Rib-Lath

¡@

|

Description: |

¡@ |

|

PS: All specifications can be ordered and made. Welcome to contact with us. |

|

Cable Tray Swaging Making Forming Machine

Automatic Brick Reinforcement Coil Making Machines

Model: CF-BRC3050 & CF-BRC2000

Description:

Automatic Brick Reinforcement Coil Making Machines This machinery produces and protects the brick reinforcement coil net.

Specification :

1.

Applicable material thickness: 0.4~0.55mm max.

2. Applicable material width: 305mm.225mm.200 mm.175mm.152 mm.100mm.63

mm max.

3. Product: 12mm (SW) * 25mm (LW) / 305 * length (mm) or13mm (SW) *

28mm (LW) / 305 * length (mm).

4. Operation area space: approximately 2 M * 10 M.

5. Applicable material: galvanized Iron or CRS or HRS.

6. Motor: 10Hp.

7. Voltage: 220/380/420.

8. S.P.M: 200~300.

|

|

|

|

¡@