Flanging Machines with Hydraulic Flange Hole Punching Machinery ROUNDO Flanging Machines with Hydraulic Flange Hole Punching Machinery china taiwan asia factory manufacturer maker comeq, machine, machinery, fabrication, fabricating, forming, metal, iron, steel, plate, sheet, angle, beam, tube, pipe, shape, section, bending roll, plate roll, rolling, bending, bender, hydraulic, ironworker, iron worker, press brake, shear, punch, mag drill, portable drill, notcher, welding positioner, adira, geka, roundo, americor, primeline, nitto kohki, bendhor, atlanta, piranha, mega, kingsland, spartan, accur, cnc control, china taiwan asia factory manufacturer maker blowers, fans

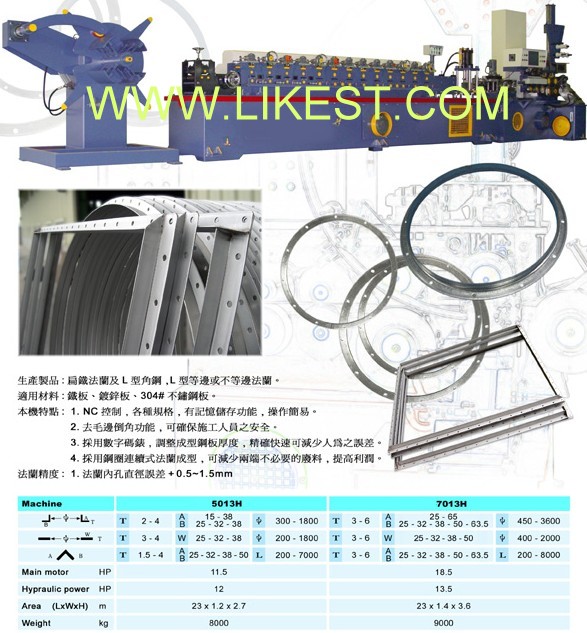

NC Digital Flanging Machine: Flange Making Machine/Flange Forming Machine/Corner Iron Making Machine/Angle Steel Making Machine / Angle Iron Ring Forming Making Machine

FL220 Double Tracks Type Flanging Machine (More Production Capacity) FL220 Flange Forming Machine/Corner Iron Making Machine/

FL210 Single Track Type Flanging Machine Equal (Unequal) Angled Flange

FL3000 Single Track Type Flanging Machine 7013H Single Track Type Flanging Machine

Human Machine Interfaces Configured HMI Systems (Configured Industrial Panel with TFT LCD Display, Touching Controllable Screen Setting), Digital Control System, Wireless Remote Control System, Attached with Module Memory Function.

NC Controller

Using Servo Motor and Hydraulic Motor synchronously to make the rotation speed adjustable according to the different production capacity.

The whole production line from feeding materials to finished products is automatic. So it can save time, materials and increase profits.

The dimension of flanges can adjustable per requirements to reduce the consumption of the materials.

With Automatic Cutting Device.

You can set process quantity.

Materials: Stainless Steel, Galvanized Steel, Iron, Carbon Steel.....

Flange Inner Diameter (D): 20"~120" (300mm~3048mm)

Max Flange Width (F): 2 inch

Max Flange Height (H): 2 inch

Capacity: ex: 800mm inner diameter flange: 500pcs~700pcs above/day (8 working hours)

Types: Single Track or Double Tracks (you don't need to adjust the moulds all the time)

Flange Width (F) for Single Track Type Flanging Machine: 1.5"*1.5" [38*38mm] (MIN.) or 2.0"*2.0" [50*50mm] (MAX.); only one size

Flange Width (F) for Double Tracks Type Flanging Machine: 1.5"*1.5" [38*38mm] (MIN.) AND 2.0"*2.0" [50*50mm] (MAX.); both sizes

Plate Thickness (T): 2mm~8mm for 1.5" Flange Width (F) ; no need to make mould if the thickness is different from 2.5mm~6mm

Suitable Material: Stainless Steel, Iron.......EQUAL-LATERAL or UNEQUAL-LATERAL angle steel and flange formation

Working Purpose: 1. To cut for various liner angle steel, 2. To cut for flange formation.

Process Speed: 7150mm/min.

Operation Function: Jogging/Automatic Function.

Body:8500mm(L)*2300mm(W)*2400mm(H), Weight: 17 Tons

Save more materials & cost: It's different with the traditional flange machine production.

Human Machine Interfaces Configured HMI Systems (Configured Industrial Panel with TFT LCD Display, Touching Controllable Screen Setting), Digital Control System, Wireless Remote Control System, Attached with Module Memory Function.

Numerical Control

Flange Inner Diameter (D): 20"~120" (508mm~3048mm)

Number of Holes that can be Punched: 360 holes (1 hole per degree)

Max Punching Diameter Range (d): Ellipse Hole: 3/8" * 1/2" (18mm*15mm); Circle Hole Diameter: 3/8" (18mm)

Production Capacity: ex: 30 holes on each flange: 250pcs above/day (8 working hours), no matter what diameter size of the flange.

Function Capacity: OB Hole Diameter 0.375" (3/8")~0.5" (1/2"), Hole Numbers:2,3,4,5,6,7,8,9............360Holes

Tolerance of the hold distance to each other: about +/- 0.004" (+/- 0.1mm)

CF 301 NC digital Circular Oil Hydraulic Hole Punching Unit Machine 1800H NC digital Circular Oil Hydraulic Hole Punching Unit Machine

(Hydraulic Flange Hole Punching/Puncturing Machine) (Hydraulic Flange Hole Punching/Puncturing Machine)

Flowchart: Forming the metal plate to a Angled Flange (Equal or Unequal )==>Cut the Angled Flange==>Welding (End to End, optional equipment)==>Punch the holes by NC Hole Punching Machine

Spiral Stainless Steel Tube Making Forming Machine Uncoiler

Applications:

The ROUND Flanging Machines are designed for easy production of flanges and pipes with flange hole punching capability!

Special design for efficient, high quality production

Our Flanging Machines is for the

production of flanges in a new way. Nearly any flange shape found on

products today can be produced with these machines. In addition,

these machines are much more efficient in production thus lowering the

cost of the product! As a good example, the manufacturing time to

flange and punch a cylinder with 1.5m (59") diameter would be less than 3

minutes with very high quality results! Due to the fact that the

cylinder is held in the machine by an expanding mandrel, the tolerances on

the diameter (roundness) will be extremely good.

In many examples it has been proven that the cost reduction by using these machines is more than 50% compared to conventional manufacturing of flanges or pipes.

Advanced capabilities with

optional tooling

Optional tooling can be added to these machines allowing many different

types of flanges. For instance, flanging material with grooves for

O-rings or with different angles. Another option is the possibility to

produce light angle rings from sheet material.

The machine has four main functions as follows...

The Expanding Unit

During the flanging operation the cylinder will be held in the

correct position by an expanding unit. This consists of a number of

segments, with the same diameter as the cylinder, which are pressed

against the inside of it. By clamping in this way the cylinder will

maintain the cylindrical form. One set of clamping segments are

required for each diameter range of the cylinders.

The Flanging Unit

The flanging is performed by some rolls. some of them is fixed and

the others is hydraulically adjustable. All rolls are driven by a

worm gear box and an electric motor. The rolls are vertical and it

means that the starting position is vertical for the cylinder. The

rolls are interchangeable for different shapes of flanges.

The Outboard Support

The supporting table for the cylinder is horizontal and the flanging

unit outboard support is hydraulically tilted into vertical position

during the flanging procedure.

The Hole Punching Unit

The machine is supplied complete with one standard hydraulic

punching unit and an indexing plate to make it possible to punch

different numbers of holes in the flanges. From there it is moved into position for punching and locked

pneumatically. The indexing plate has two circles with different

amounts of holes. The indexing is made by manual rotation and the

positions are set pneumatically.

Examples of Flanges

~Special Design Welcome~

Optional Equipment

Interchangeable Rolls (1 fixed, 1 hydraulically adjustable)

Segmented Clamping Expanding Unit

Hydraulic Outboard Support

Hydraulic Flange Hole Punching Unit with Standard Indexing Plate

Automatic Flanging Operation

Different sets of Expanding Dies

Different sets of Punch and Dies

Extra set of Flanging Rolls

Special Indexing Plates by customer request

Compare to the other Flange Machine:

WE CAN ALSO MAKE FLANGES FOR YOU. China Price but Taiwan Quality!

We are

one of the leading manufacturing company specialized in the fabrication of

Ducting & Fittings for both Air-Conditioning & Ventilation System.

We supply One-Stop Air-Conditioning Ducting & Accessories.

PROTECTION EDGE MACHINE for Steel Roll Packing

PROTECTION EDGE MACHINE for Steel Roll Packing

IW-500L NC Digital Linear Puncturing Machine (Punching Machine) NEW

IW500DL NC Digital Dual Cylinder Linear Pipe/Tube Punching Machine

TDC Flange Forming Machine

FL22 Double Tracks Type Flanging Machine (More Production Capacity)

FL22 Flange Forming Machine/Corner Iron Making Machine/Angle Steel Making Machine