|

||||||||||||||||||||||

|

About us | Machinery | NEW | Contact us |

||||||||||||||||||||||

|

Punching and Shearing (Cutting) Machines for Beams, Flats & Angles |

||||||||||||||||||||||

|

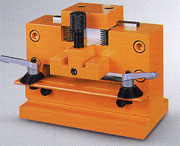

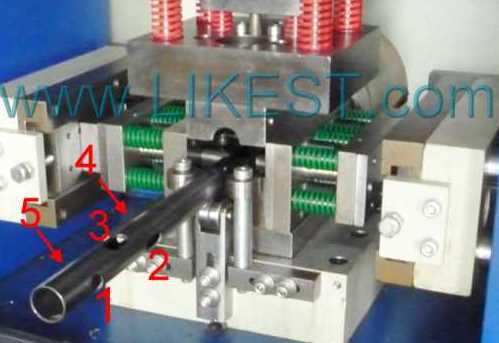

single Cylinder Tube Punching Machine |

Dual Cylinders Tube Punching Machine |

|||||||||||||||||||||

|

Punched Samples: |

||||||||||||||||||||||

|

Specification (SPECIAL DESIGN IS WELCOME)

|

||||||||||||||||||||||

|

Features

|

||||||||||||||||||||||

|

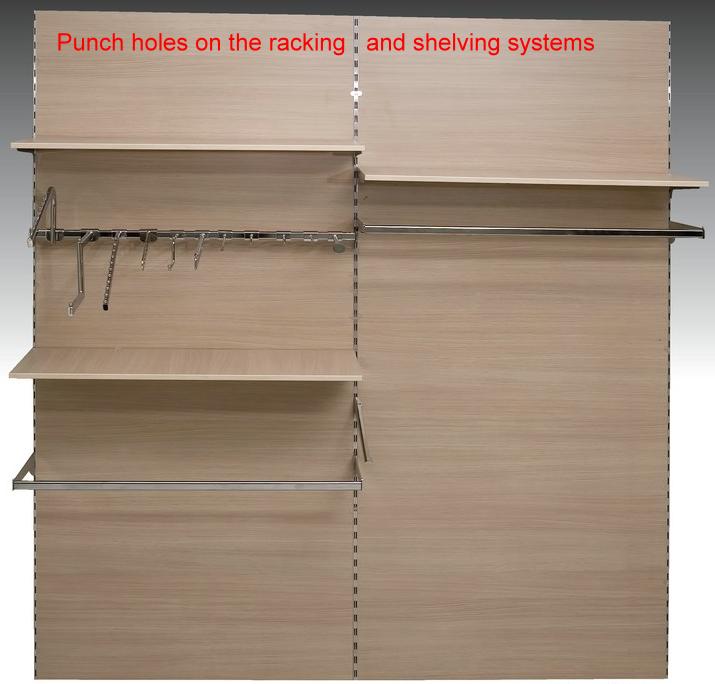

Applications (SPECIAL DESIGN OR BIGGER PRODUCT SIZE IS WELCOME) Plates-punching and cutting machines for Telecom Tower, Mast, Monopole, BTS Shelter, OF Cabling, Transmission Tower Structural Members Manufacturing Plant, MOBILE SHELVING SYSTEM, Bed, Furniture, Scaffolding (Ring Lock & CUP Lock, Tours, Frame Systems, Table type, Props, Accessories), LADDERS, truck body builders, display stand, metalworking industries manufacturing for Automotive Manufacturing,Gas Stove, power energy and electrical wire distribution, Racking and Shelving and base of your Custom Signs, Electronic Displays, Resorts & Casinos, Outdoor Media and Repairs & Maintenance, high volume and different purpose punching for Rectangle Tube/Round Tube/Circle Tube/Square Tube/Ellipse Tube/Perforation and much more...... For 12meters length materials (Beams, Flat Iron & Angle Steel....), application for Electricity Tower/Electricity Pole/Electrical Tower/BTS Tower/Lighting Pole/Transmission Tower Structural Members Manufacturing Plant, Metal Scaffolding Making Forming Machine......

|

||||||||||||||||||||||

|

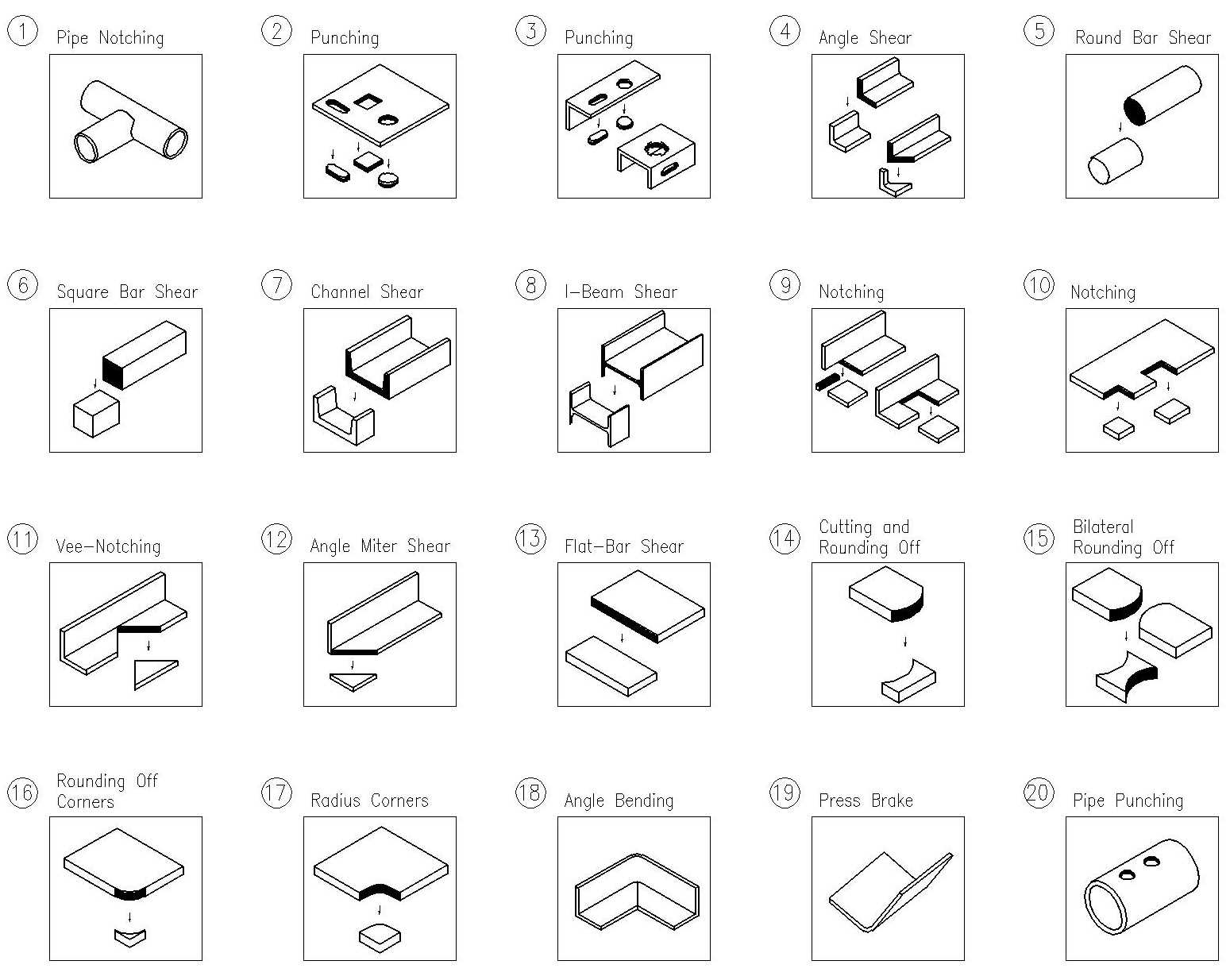

Optional Punching Die/Tooling/Mold for punching machines:

|

||||||||||||||||||||||

|

Special Requirements Mould/Tooling/Mold is WELCOME |

||||||||||||||||||||||

|

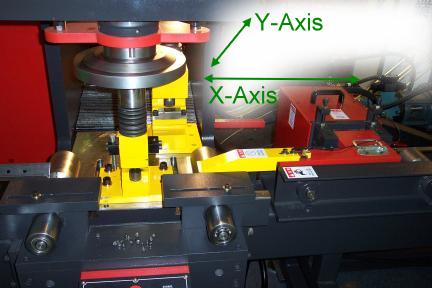

Punching Machine Operation:

|

||||||||||||||||||||||

prop sleeve punching machine,Servo Controlled Hydraulic Channel Hole Punching Machine,Servo Controlled Hydraulic Square Pipe Hole Punching Machine,

Round

Tube: 1"~6inch (25.4 ~150mm)

Round

Tube: 1"~6inch (25.4 ~150mm) Square Tube: 25*25~106*106m (1"~4.17inch)

Square Tube: 25*25~106*106m (1"~4.17inch) Rectangle/Oblong

Tube:

20*40~75*130mm

Rectangle/Oblong

Tube:

20*40~75*130mm Ellipse Tube:

Ellipse Tube: